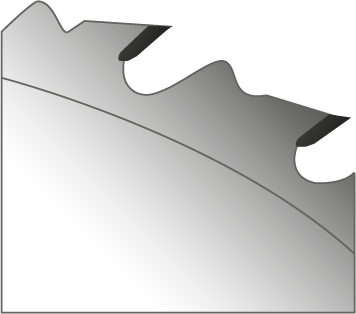

A Widia disc consists of a carbon steel blade and welded tungsten carbide teeth. Used to cut wood (hard, soft, nails), plywood, chipboard, laminate, aluminum, or ferrous materials.

The main characteristic of this type of disc is its teeth, which vary in number and shape according to the material for which they are prepared to cut. That is why it is essential to know their geometry.

How is a Widia Disc?

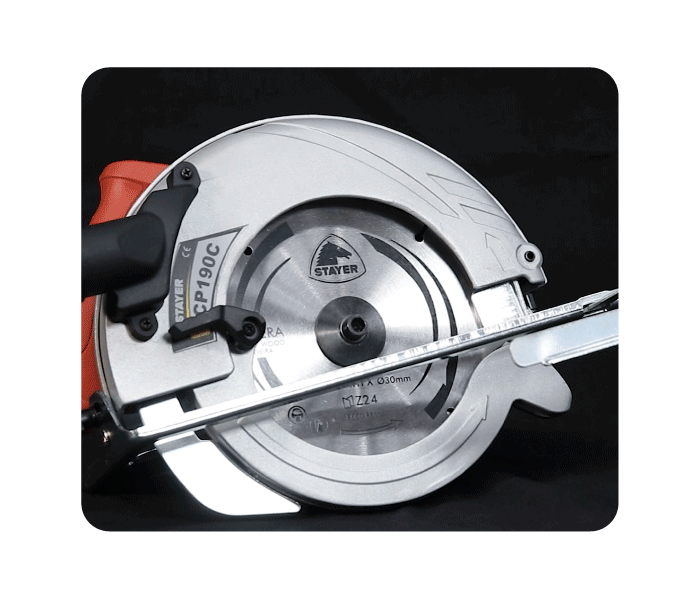

As explained before, Stayer Widia discs are made of a high-strength carbon steel blade and can be of two qualities: standard (STD) or high Quality (HQ).

HQ blades differ from standard blades: less noise, heating, vibrations, and torsion of the blade during cutting.

«And what is this due to?»

To the laser grooves that they may have in the center of the blade or to the expansion grooves on the edges.

The expansion grooves are responsible for the edge of the disc to have less heating during cutting, is much better and, in addition, the teeth have a longer useful life, the plate does not twist and there is greater resistance to torsion.

However, the laser grooves are going to oversee absorbing the vibrations contributing to a lower noise level. For this reason, it is called Semi-Silent (SS) blade.

But the main characteristic of a Widia disc is the teeth. Do you want to know why? Keep reading.

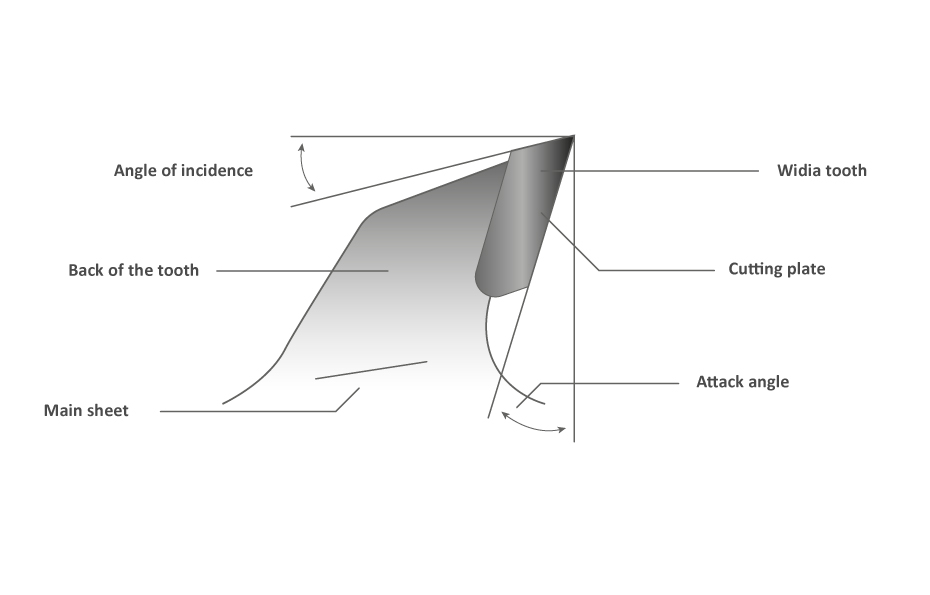

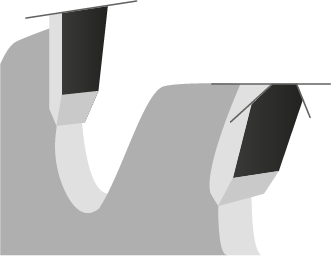

Parts of the teeth of a Widia disc

As shown in the picture, Tungsten Carbide teeth consist of the following parts:

- The cutting blade, in charge of cutting. Where the angle of attack and incidence is of special importance.

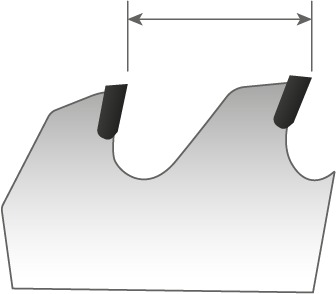

- The pitch, which marks the distance between the teeth and the number of teeth. The greater the distance, the smaller number of teeth and vice versa.

- And the geometry of the tooth which, depending on the material to be cut, can be flat, alternating, or trapezoidal-flat.

Next, we will explain each part in more detail.

The cutting blade or tooth of Tungsten Carbide (Widia):

The blade oversees making the cut and it will differ depending on the angle of attack and incidence it has.

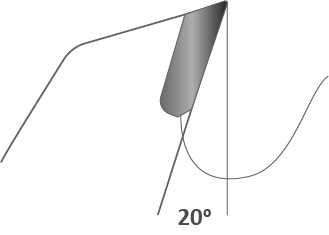

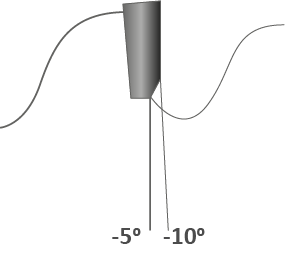

The angle of attack indicates the inclination of the teeth considering the rotation. And these can be positive or negative to varying degrees.

The larger the positive angle of attack, the more aggressive and faster the cut will be. Therefore, the chances of the material chipping and the tooth being damaged are higher. That is why it is recommend that they must be used with soft materials such as wood, so that it is easier to cut it without any problem.

But if the angle of attack is negative, the opposite happens. The cut is slower and more precise and that is why it is convenient to use it with hard materials such as aluminum or laminates.

However, the angle of incidence will depend directly on the angle of attack, the height and geometry of the tooth. According to these three variables it will be higher or lower.

The pitch and number of teeth

When we talk about the pitch, we refer to the distance between the teeth of the disc. When it is larger, there are fewer teeth and therefore the cut is much faster and less precise. On the contrary, when it is smaller, the number of teeth is greater, and the cut is slower and more exact.

«And how should they be depending on the material you are going to cut?»

If it is very thick, it is better if the disc had fewer teeth. This will prevent it from getting stuck or hot by improperly dislodging the chip and therefore cutting more slowly.

However, if the material is very hard, it is better that the disc has a greater number of teeth to avoid damage during the process.

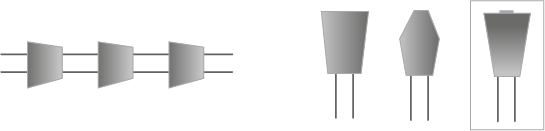

Tooth geometry

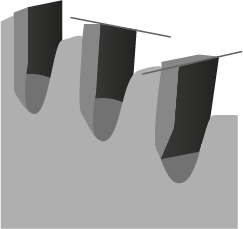

As for the geometry of the teeth there is a lot of variety. At Stayer we have ATB blades for cutting wood and TCG blades for cutting laminates, aluminum, and metal. Among the different types we offer you will find:

Alternate -Top Bevel (ATB): with the edge of the teeth oblique and the direction of each alternate from left to right to prevent the wood from splintering.

ATB with protection system: to cut wood with nails without damaging the teeth.

TCG (Triple Chip Grind): with a flat tooth followed by another trapezoidal to break the chip into 3 parts and in this way the finish is perfect.

And Sandwich tooth TCG: with a very small throat depth for cutting materials such as steel.

After knowing what are the parts of a Widia disc, you will say «How is it manufactured so that the cut is perfect and does not crack or break during the process?» We explain it to yo

Making a Widia Disc

- In the first place, the steel blade is laser cut to guarantee that the surface is extra flat, has a good tension and therefore is resistant to extreme working conditions.

- Afterwards, a grinding of the seat of the tooth is made so that there is no unforeseen event in its adherence.

- Next, the Tungsten Carbide teeth are welded and sandblasted to confirm that the weld is perfect and will not break during cutting.

- At this point, the tooth plate is sharpened considering its angle of attack depending on the use it is going to have.

- And finally, once it is checked that the disc meets all the conditions, it is marked and labeled.

At Stayer we have Widia blades for circular saws or miter saws

At Stayer we have several models of Widia blades for cutting wood, laminates, aluminum, and metal with a circular or miter saw. If you are interested in knowing them, access our accessories catalogue, in it you will find all the specifications you need about Widia discs.